By Roberto Molar Candanosa

News at Northeastern

You’ve probably heard that homemade masks can prevent you from inadvertently spreading the coronavirus when you cough, sneeze, talk, sing, laugh, or breathe out. You may have also heard that they can’t be as effective at blocking viral particles as N95 respirators, the type of masks designed and tested to prevent medical staff from inhaling harmful microbes such as the SARS-CoV-2 coronavirus that causes COVID-19.

Steve Lustig is an associate professor and the associate chair of research in chemical engineering at the College of Engineering at Northeastern. Photo by Matthew Modoono/Northeastern University

But when Steve Lustig goes out for a walk, he covers his face with a homemade mask that has the same ability to stop viral particles as an N95. His mask consists of a pair of layers of terry cloth. And Lustig, an associate professor of chemical engineering at Northeastern, trusts it because he and his team tested those materials in the lab.

After testing how nanoparticles penetrated more than 70 combinations of fabrics, the team found several combinations of common materials that can be as effective at blocking coronavirus particles as N95s—or better. The trick, Lustig says, is that the fabrics must be layered tactically.

“Most fabrics aren’t as good as the official, certified N95 respirators.” Lustig says. “But no one had really asked the question of how many layers it would take for cotton, for example, to be as good as an N95.”

One of the most important aspects of how to lay fabric that can block viral particles is to combine materials that have enough fibers to increase their chances of trapping, or absorbing, germs.

Another key part of that puzzle is to use at least one layer with hydrophobic properties, which would repel aqueous substances such as respiratory droplets from someone’s airway and prevent them from passing through the mask. If the liquid wets the fabric, it can move viral material through it.

That combination of layers, in addition to a snug fit around the face and proper physical distancing, can make for a significant defense system, Lustig says.

A particle of SARS-CoV-2 is no larger than a white blood cell or a light dust particle, which human eyes can’t see without a microscope. The coronavirus gets its name from a set of crown-like spikes that surround its tightly packed genetic material.

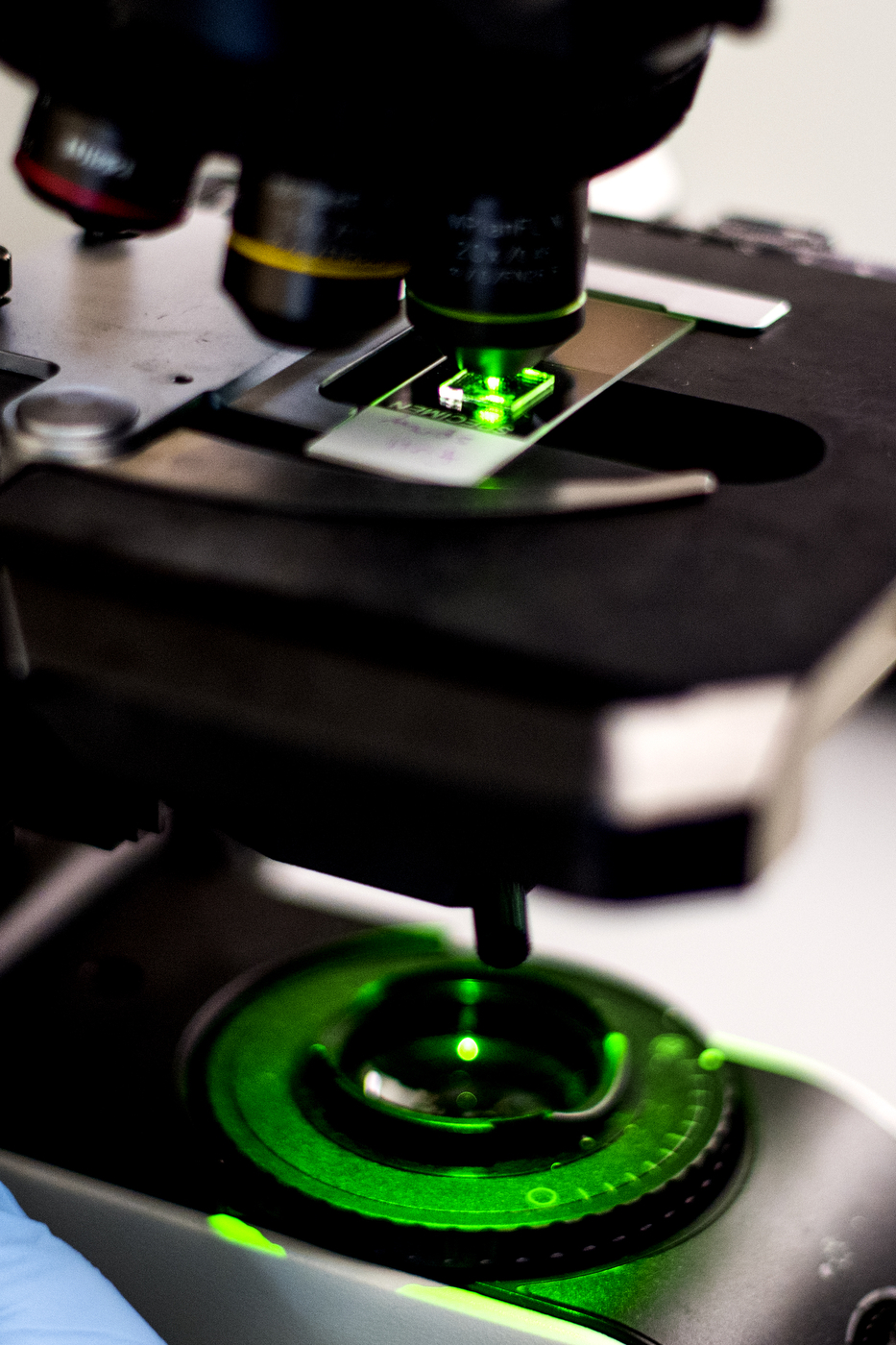

To study how such a tiny and peculiar particle passes through a material, Lustig worked with Ming Su, a professor of chemical engineering at Northeastern. Su’s team had been developing fluorescent nanoparticles.

Because those nanoparticles were so similar in size to the coronavirus, and because they interact in a similar way to the way that SARS-CoV-2 interacts with water, Su prepared a batch specifically for the experiments at Lustig’s lab. The idea was also to take advantage of the fluorescence of the nanoparticles to count them after they passed through the fabric using a special microscope.

Lustig’s team dispersed the nanoparticles in water and then sprayed that substance into the air to emulate a coughing and a sneezing from someone carrying the virus. The tests also created different changes in airflow to account for the kind of dynamics a wearer creates by breathing, which helps viral particles pass through a material.

“You’re also breathing through the mask, so we had to replicate that in a physically and biologically meaningful way,” Lustig says. “There was a lot of trial and error about what kind of flow rates we should use, what kind of concentrations of nanoparticles, and how quickly the nanoparticles should be sprayed.”

The findings show that absorbent layers that can stop coronavirus particles with the same or higher efficiency of an N95 mask include those using terry cloth, quilting cotton, and flannel. The best water-repellent layers to add in those combinations involve nonwoven polypropylene—Lustig’s team tested OLY-Fun fabric—and materials consisting of polyester and polyaramid, a blend used in lab coat fabric.

The team also tested cotton coated with Scotchgard, a commercial fabric and upholstery protector that repels water. That’s one way to turn a fabric into a decent water-repelling barrier, Lustig says.

“With many kinds of cotton, one or two layers won’t work,” he says. “But multiple layers will be effective, and if you at least have one or two layers that are hydrophobic, you’re going to get pretty good protection.”

Scotchgard can come in handy. But people should not breathe the spray directly, and should not use it in layers of fabric that sit closest to the mouth, Lustig says. The idea is to use Scotchgard if that’s the only option people have for a water repellent, spray it on the outer or middle layer of a mask, and let it dry before putting it on.

Like viral droplets expelled by a person, water droplets carrying the nanoparticles can accumulate on the surface of a material. That may make it seem as if the particles will not pass through it. But the team’s tests showed that the absorbance of a material alone does not speak to its abilities to block the virus-like particles.

When droplets accumulated on the surface of the materials the team tested, changes in the air flow designed to replicate the breathing of a mask wearer helped the nanoparticles pass through.

“This is a real possibility, because if you sneeze and it’s a big sneeze, or if you have a wet kind of cough, you can flood your mask,” Lustig says, explaining that there are other ways in which a mask can get wet, like when sneezing or coughing from someone else floods the outer layer of a mask.

“That’s the purpose of the hydrophobic layers,” he says. “To make sure that the aerosols don’t permeate all the way through if someone sneezes on your mask, that you’re not picking up that virus particle when your tongue touches the mask.”

Because of the effect that breathing could have on the efficiency of a face mask, Lustig says that trying to change the way people breathe can also help people in situations where they face a higher risk of inhaling the coronavirus.

“If someone has just sneezed in front of you, and they’re not wearing a mask, you’re better off just holding your breath while you walk past that, or turning around to walk away before you start breathing heavily into your mask again,” Lustig says.

The team began designing the experiment soon after they read in an email that Michael Rosenblatt, chief medical officer at the Lahey Hospital and Medical Center, was asking for help to test common fabric materials that medical staff could use in the midst of mask shortages in the U.S.

The U.S. Army and the U.S. Department of Agriculture have also experienced shortages of face masks, and they have also used the team’s research, Lustig says.

“They needed science-based answers,” he says. “We realized we’d rather help than stand by.”

(Reprinted with permission from the News at Northeastern.)